The Importance of Proper Industrial Hose Assembly Installation

A rightly installed industrial hose assembly is essential for safe, efficient, and reliable operation across industrial environments. Proper installation ensures that each assembly and its connected industrial hoses perform at their designed capacity, withstand operational pressures, and maintain integrity over time. Without careful attention, hoses are prone to premature wear, leaks, or even catastrophic blowouts, which can lead to costly downtime, production delays, and safety hazards.

Common issues caused by improper installation include fluid or air leaks, detachment of fittings, pressure loss, and unexpected hose failures. Such problems disrupt operations and put personnel and equipment at risk, making correct installation practices vital for any industrial setting. In addition, poorly installed industrial hoses can accelerate wear on connected machinery, reduce system efficiency, and increase maintenance costs over time.

Another major factor is safety. An improperly installed industrial hose assembly in high-pressure or chemical applications can result in hazardous spills, injuries, or environmental contamination. Organizations that overlook installation standards expose themselves to regulatory risks, insurance liabilities, and operational shutdowns.

As a leading industrial hose manufacturer, DAE Hose provides engineered solutions that prioritize safety, reliability, and operational efficiency. Their industrial hoses and assemblies undergo rigorous quality checks, including pressure testing, chemical compatibility verification, and adherence to industry standards. This ensures consistent performance across mining, manufacturing, oil and gas, construction, and other demanding sectors.

Choosing a certified industrial hose manufacturer like DAE Hose guarantees access to expertly designed assemblies that deliver long service life, reduced downtime, and measurable ROI. By focusing on proper installation and high-quality components, organizations can protect personnel, improve system performance, and ensure that every industrial hose assembly meets both operational and safety requirements.

Understanding Industrial Hose Assemblies

What Is an Industrial Hose Assembly?

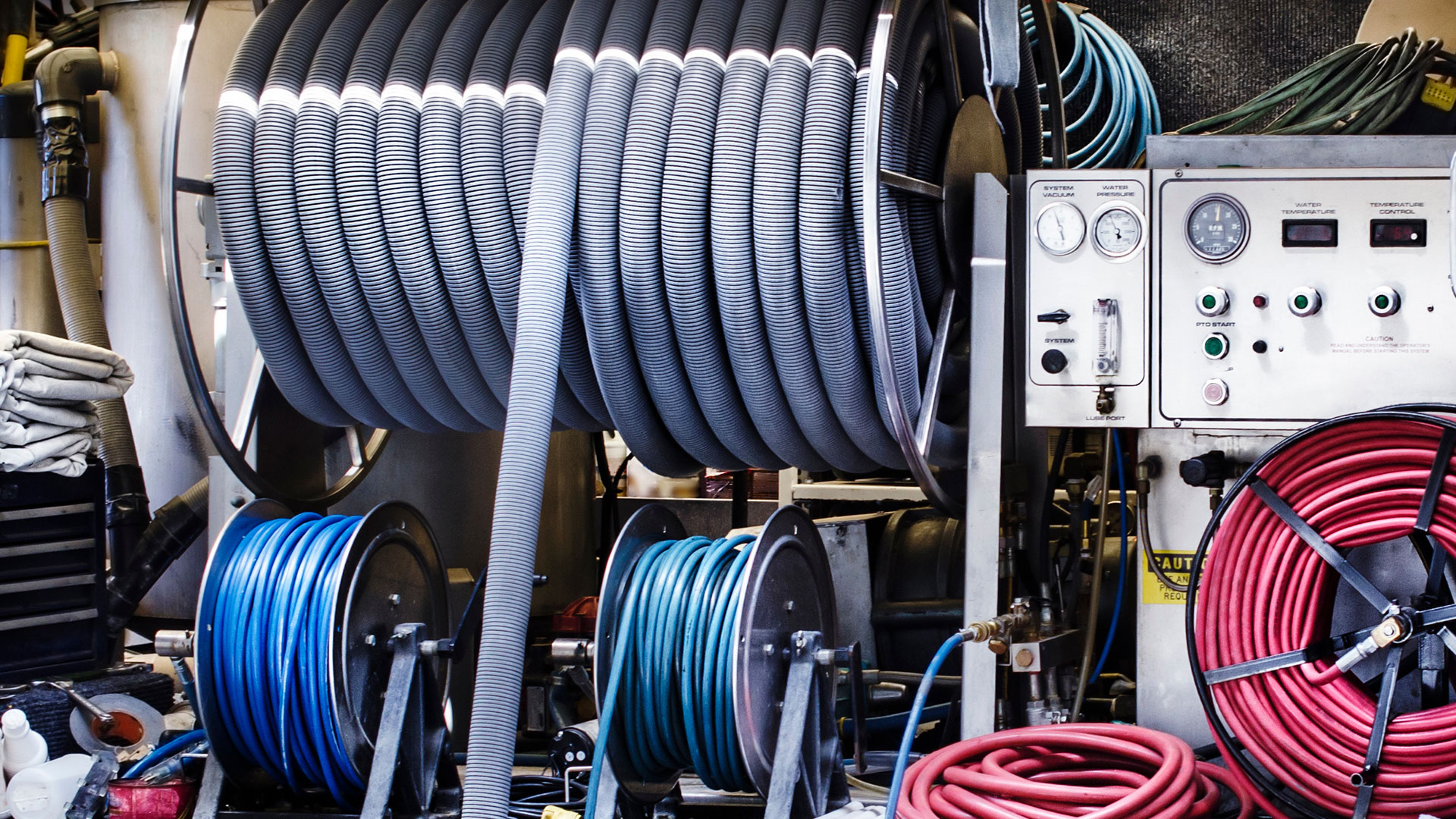

An industrial hose assembly is a pre-engineered system designed to safely and efficiently transfer fluids, gases, or other materials in industrial environments. Each assembly combines multiple components, hose body, fittings, couplings, and clamps, to ensure a secure, leak-free connection capable of withstanding specific operational pressures and temperatures.

Unlike standard hoses, an industrial hose assembly is tested for pressure resistance, chemical compatibility, and durability. Properly constructed assemblies reduce the risk of leaks, blowouts, or operational downtime. High-quality industrial hoses from certified manufacturers, such as DAE Hose, deliver reliable performance across a variety of industrial applications.

Industrial hoses differ from hydraulic hoses in key ways:

- Industrial hoses are adaptable and can carry a variety of fluids, including air, water, chemicals, and petroleum. They often work under low to medium stress and promote flexibility.

- Hydraulic hoses are designed for high-pressure fluid transmission in machines and frequently have multi-layered reinforcement, such as steel wire or textile braiding. Understanding these distinctions is critical for picking the appropriate assembly for each application.

Industrial Hose Types and Applications

Industrial hose assemblies are available in multiple types to suit specific operational needs:

- Air Hoses: Commonly used in manufacturing, construction, and pneumatic tool systems.

- Water Hoses: Employed for cooling, irrigation, and general fluid transfer.

- Chemical Hoses: Designed to handle acids, solvents, and corrosive liquids safely.

- Food-Grade Hoses: Constructed from hygienic materials for food and beverage processing.

- Petroleum Hoses: Resistant to fuels and oils, ideal for refineries and fuel distribution.

Industrial hose assemblies find applications across a wide range of industries:

- Mining: Slurry transport, water transfer, and pneumatic systems.

- Construction: Water delivery, compressed air, and material handling.

- Manufacturing: Cooling systems, chemical transfer, and process fluid handling.

- Oil & Gas: Fuel transfer, chemical injection, and refinery operations.

Selecting the right industrial hose assembly for each application ensures operational efficiency, safety, and long-term reliability. Partnering with a trusted industrial hose manufacturer ensures the assembly meets the pressure, temperature, and media-compatibility requirements for its intended industry.

Step 1: Define Application and Hose Requirements

The first step in installing a reliable industrial hose assembly is to define the application and operational requirements clearly. Understanding the medium, temperature, and pressure range is critical to selecting a hose that performs safely and efficiently. Using a hose that cannot withstand the system’s operating conditions can lead to leaks, bursts, or premature wear, increasing maintenance costs and operational downtime.

Material compatibility is another essential consideration. Industrial hoses are available in rubber, PVC, polyurethane, and composite materials, each suited for specific fluids, chemicals, or environmental conditions. Selecting the right material ensures that the hose resists chemical attack, maintains flexibility, and delivers long-term performance.

Additionally, defining the minimum bend radius and incorporating an appropriate safety factor are crucial for reliable operation. Exceeding the bend radius can cause kinks or stress on the hose reinforcement. At the same time, a proper safety factor ensures that the industrial hose assembly can tolerate unexpected pressure surges or mechanical stress.

By carefully defining application requirements, organizations ensure that each industrial hose assembly meets performance expectations, enhances safety, and minimizes downtime. Partnering with a certified industrial hose manufacturer like DAE Hose ensures guidance on material selection, pressure ratings, and industry-specific requirements, delivering safe, efficient, and durable assemblies.

Step 2: Choose the Right Hose and Fittings

Selecting the correct hose and fittings is a critical step in ensuring a safe, reliable, and efficient industrial hose assembly. Choosing incompatible components can result in leaks, system downtime, and safety hazards. Careful attention to hose specifications and fittings ensures optimal performance across demanding industrial applications.

Hose Selection

Hose selection begins with understanding the operational requirements of the industrial hose assembly. Key factors include:

- Size and Diameter: Proper sizing is crucial for maintaining correct flow rates and avoiding excessive pressure loss. A hose that is too small restricts flow, while an oversized hose can create turbulence or bending issues.

- Pressure Rating and Reinforcement: Hoses are designed to handle specific pressure ranges. Low to medium-pressure applications may use textile-reinforced hoses, while high-pressure systems, such as hydraulic applications, require multi-layer steel-wire reinforcement to ensure durability.

- Material Compatibility: The hose material must match the transported medium. Rubber, PVC, polyurethane, and composite hoses are chosen based on chemical resistance, flexibility, and temperature tolerance. Proper material selection prevents degradation, leaks, and potential system failures.

By carefully selecting hoses, organizations ensure their industrial hose assemblies operate safely and efficiently, reduce maintenance costs, and prolong service life.

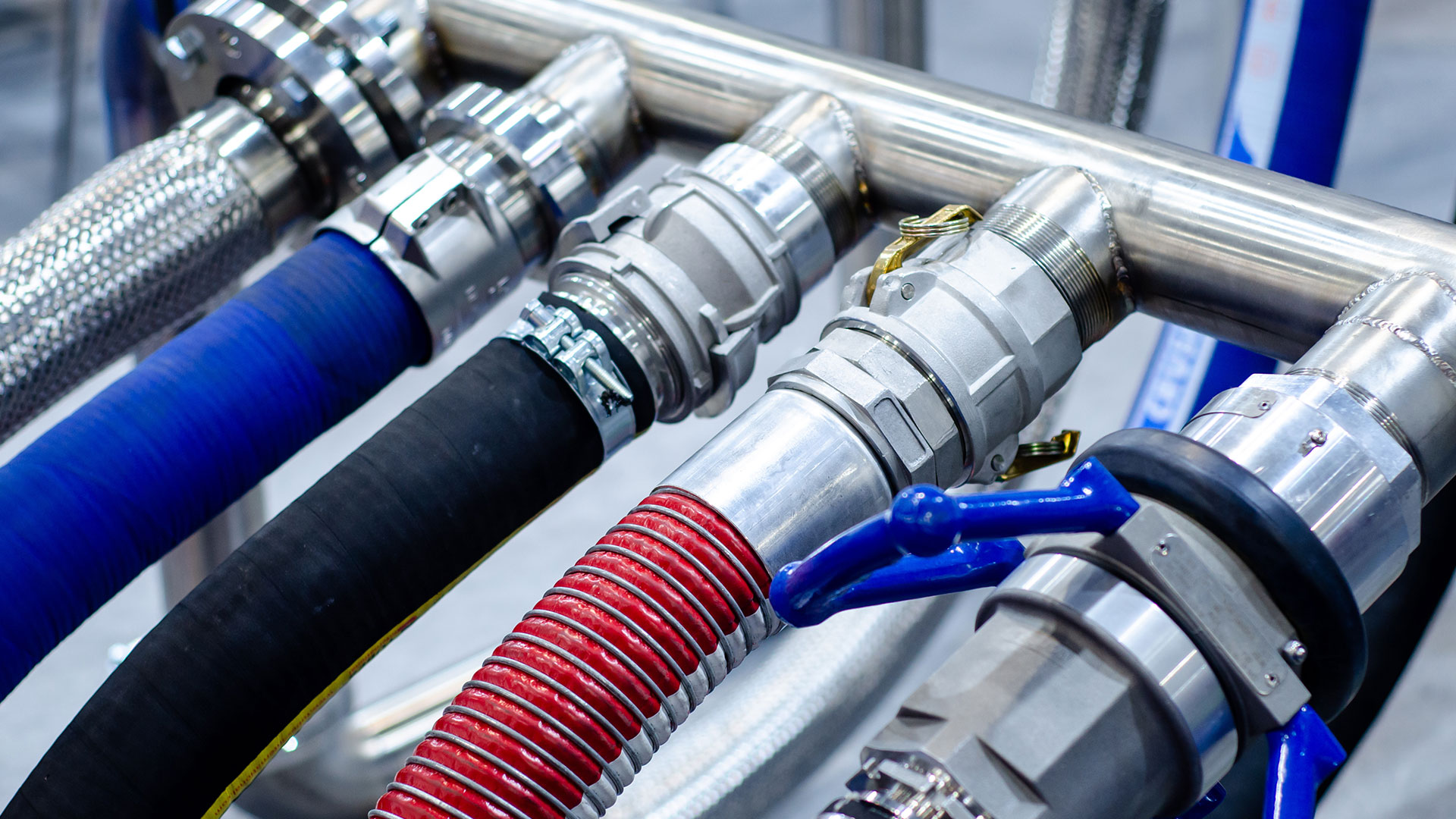

Fitting and Coupling Selection

Fittings and couplings play an important part in the integrity of an industrial hose assembly. Incorrectly matched components are a leading source of leakage and catastrophic failures. Consider the following.

- Material Selection: Fittings are typically made from brass, stainless steel, or aluminum, selected for compatibility with both the hose and the transported medium.

- Thread Type and Size: Correct thread matching prevents cross-threading, leaks, and improper sealing. Using mismatched threads can compromise the assembly under pressure.

- Coupling Design: Camlocks, flanges, or quick-connect fittings should be chosen based on operational requirements, including connection frequency, pressure rating, and industry standards.

Partnering with a certified industrial hose manufacturer like DAE Hose ensures that hoses, fittings, and couplings are fully compatible, rigorously tested, and engineered for specific industrial applications. Correct selection maximizes performance, minimizes maintenance, and ensures the long-term reliability of every industrial hose assembly.

Step 3: Prepare for Installation

Proper preparation is essential to ensure a safe and effective installation of industrial hose assemblies. Even high-quality hoses can fail prematurely if preparation is overlooked. Careful inspection, workspace setup, and proper handling are critical steps in maintaining system performance and safety.

Inspect Hose and Fittings for Defects or Damage

Before installation, thoroughly examine each component of the industrial hose assembly. Look for:

- Cracks, abrasions, or soft spots along the hose body.

- Deformed, corroded, or loose fittings and couplings.

- Manufacturing defects such as irregular reinforcement or wall thickness.

Identifying possible problems at this point avoids leaks, blowouts, and operational downtime once the assembly is in service. Working with a reliable industrial hose manufacturer ensures that all hoses and fittings meet high-quality standards before delivery.

Ensure Proper Tools, Workspace, and PPE

A safe installation environment is essential. To avoid damaging the hose or fittings, operators should use appropriate tools, including torque wrenches, cutting tools, and clamps. To prevent contamination or mishaps, the workstation should be clean, free of debris, and well-organized. Personal protection equipment (PPE), such as gloves, safety goggles, and protective gear, protects workers during handling and assembly.

Clean and Cut the Hose to the Required Length

Accurate hose length is critical for maintaining proper bend radius and preventing stress on fittings. Before cutting, clean the hose internally and externally to remove dirt, dust, and other debris that could compromise performance. Use precise cutting tools to ensure square, smooth ends that facilitate secure couplings.

By following these preparation steps, organizations ensure that each industrial hose assembly is ready for a safe, efficient, and long-lasting installation. Proper preparation minimizes operational risks, protects personnel, and extends the service life of hoses and connected equipment.

Step 4: Assemble and Secure the Hose

Proper assembly and securing of an industrial hose assembly are among the most critical steps in ensuring operational safety, reliability, and system efficiency. Even small errors during assembly can lead to leaks, equipment damage, or catastrophic failures. Following best practices, using proper tools, and adhering to manufacturer specifications are essential for a robust and long-lasting installation.

Crimping and Coupling Process

The crimping and coupling process ensures that the hose is securely connected to its fittings and can withstand operational pressures. Key considerations include:

- Correct Insertion Depth and Alignment: Proper insertion of the hose into the fitting is vital. The hose should sit fully within the coupling without excessive slack or misalignment. Misaligned assemblies can create uneven stress on the hose and couplings, increasing the risk of leaks or failures.

- Adherence to Manufacturer Crimp Specifications: Every industrial hose assembly must meet the manufacturer-specified crimp dimensions and torque requirements. Using certified crimping tools ensures consistent pressure and avoids over-crimping, which can damage hose reinforcement, or under-crimping, which can lead to loose fittings.

- Selection of Compatible Components: Only use fittings, couplings, and clamps recommended by the manufacturer. Mismatched or incompatible components are a common source of failure, leading to blowouts or hazardous leaks.

- Multiple Verification Steps: Before finalizing the crimp, operators should double-check that the hose and coupling alignment is correct and that the crimping tool is properly calibrated for the hose type and diameter.

Proper execution of this step ensures that the industrial hose assembly is structurally sound and capable of safely handling system pressures.

Verification and Testing

After assembly, verification, and testing, confirm the integrity and performance of the hose system. Best practices include:

- Visual Inspection: Examine the assembly for correct crimp patterns, uniform compression, proper alignment, and absence of visible damage. A visual check can catch potential issues before pressurization.

- Pressure Testing: Conduct hydrostatic or pneumatic tests at or slightly above the system’s maximum working pressure. This step validates that the assembly can handle operational loads without leaks or deformation. For chemical or petroleum applications, this testing is especially critical to prevent hazardous spills.

- Documentation and Traceability: Record all assembly details, including hose type, fitting specifications, crimping parameters, and pressure test results. Maintaining detailed records supports regulatory compliance, facilitates future maintenance, and provides traceability during system audits.

- Periodic Re-Verification: For systems operating under high pressure or extreme conditions, periodic re-inspection and testing of assemblies ensure ongoing safety and performance over time.

Following these assembly and verification protocols ensures that each industrial hose assembly is safe and efficient. Working with a renowned industrial hose manufacturer, such as DAE Hose, ensures that hoses, fittings, and couplings are developed, tested, and certified to industry standards, reducing the risk of failure and extending the assembly’s service life. Proper assembly also lowers downtime, protects staff, and maximizes ROI by avoiding costly operational disruptions.

Maintenance and Inspection Best Practices

Routine maintenance and inspection are crucial for the long-term safety and performance of an industrial hose assembly. Even high-quality industrial hoses can experience wear due to abrasion, pressure fluctuations, or exposure to harsh chemicals. Implementing a structured inspection and maintenance program helps prevent leaks, minimize downtime, and extend the overall life of the hose.

Routine Checks for Wear or Leaks

Regular inspections are key to identifying early signs of damage in industrial hose assemblies.

- Hose Body: Look for cracks, cuts, bulges, or soft spots that may indicate internal damage.

- Fittings and Couplings: Check for corrosion, looseness, or physical damage that could cause leaks.

- Chemical or Environmental Damage: Ensure the hose material remains intact and hasn’t degraded due to chemical exposure, UV radiation, or extreme temperatures.

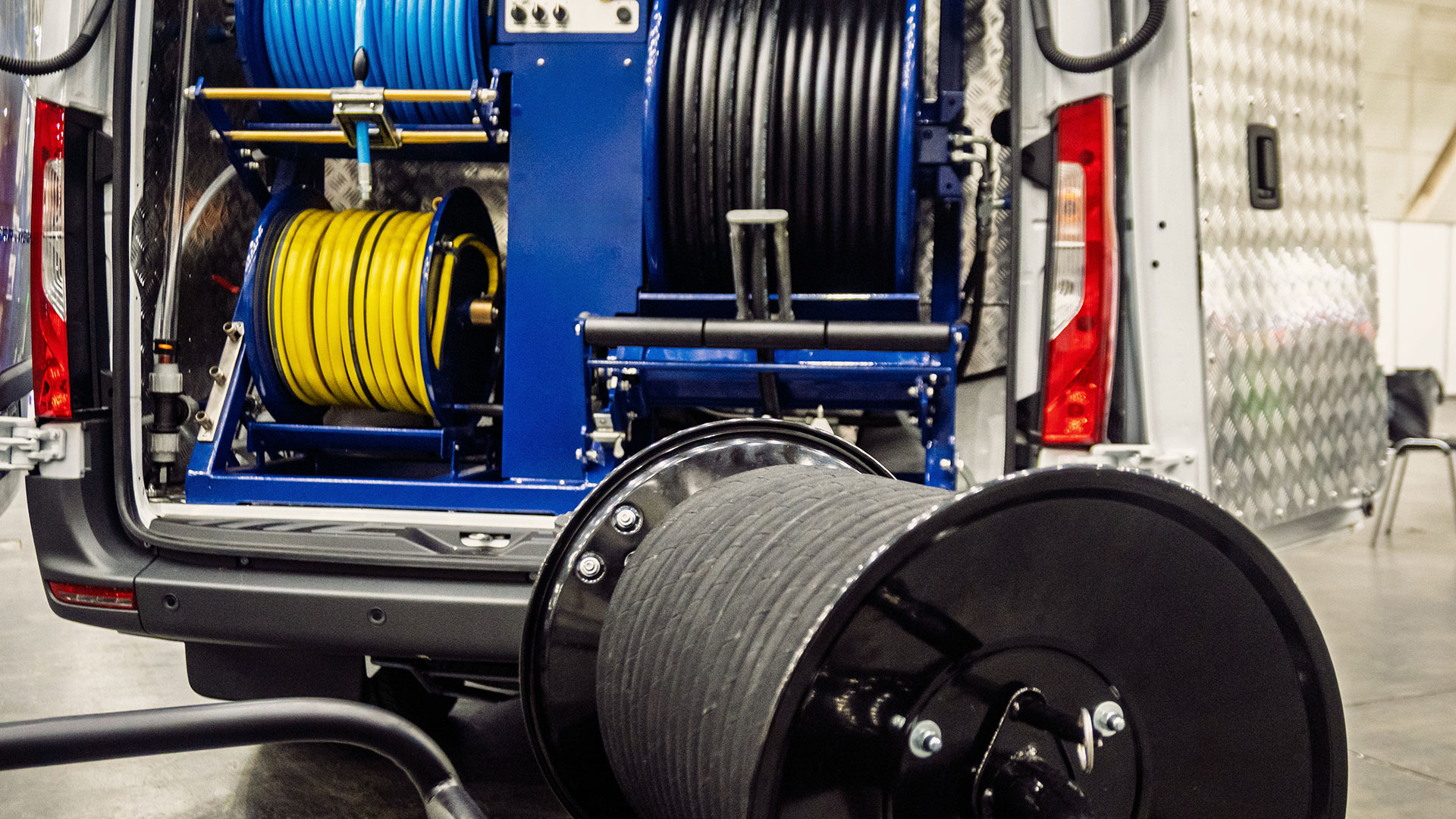

Proper Storage and Handling

Proper storage and handling significantly extend the life of industrial hoses.

- After Use: Clean hoses thoroughly to remove chemical, petroleum, or abrasive residues.

- Storage: Keep hoses in a cool, dry location away from direct sunlight, heat sources, or sharp edges.

- Handling: Avoid dragging hoses over rough surfaces and maintain the recommended bend radius to prevent structural damage.

Consulting an Industrial Hose Manufacturer

In some cases, professional support is essential to ensure safe and efficient operations.

- Replace damaged or worn hoses immediately to prevent failures.

- Schedule periodic re-certification for high-pressure or specialty assemblies.

- Seek expert guidance from a trusted industrial hose manufacturer like DAE Hose for advice on installation, compatibility, and maintenance procedures.

Following these best practices guarantees that every industrial hose assembly runs safely, effectively, and reliably, resulting in consistent industrial performance and long-term cost benefits.

Cost, Performance, and Long-Term ROI

Investing in a high-quality industrial hose assembly reduces downtime, minimizes maintenance costs, and ensures safe, reliable operation. Properly selected and installed assemblies help maintain system efficiency and extend service life, lowering the total cost of ownership over time.

Selecting the right industrial hoses for specific mediums, pressures, and temperatures ensures optimal performance and prevents premature wear or failure. Certified assemblies from a trusted industrial hose manufacturer, such as DAE Hose, ensure perfect compatibility between hoses and fittings, reduce the risk of leaks or operational disruptions, and enhance overall system reliability.

By choosing well-engineered industrial hose assemblies and high-performance industrial hoses, organizations can increase efficiency, protect personnel and equipment, and achieve measurable long-term ROI. Partnering with a certified industrial hose manufacturer ensures consistent quality, safety, and value across all applications.

Ensuring Safety and Efficiency with Industrial Hose Assemblies

Proper installation, selection, and maintenance of an industrial hose assembly are essential for safe, dependable, and effective operations. Organizations may reduce leaks, save downtime, and prolong service life by establishing application requirements, selecting appropriate hose and fittings, and adhering to best practices for thorough preparation, assembly, and inspection.

Partnering with a trusted industrial hose manufacturer like DAE Hose ensures access to high-quality products, technical guidance, and certified assemblies that deliver consistent performance across industries. Their range of industrial hoses is designed to meet diverse operational needs, from high-pressure systems to chemical transfer and material handling applications.

Investing in well-engineered industrial hoses and assemblies not only safeguards personnel and equipment but also provides measurable long-term ROI. For companies seeking durability and dependability, working with a certified industrial hose manufacturer like DAE Hose remains a strategic decision that enhances productivity and operational safety.