Water supply systems are a critical aspect of operations across various industries, from emergency response scenarios to routine industrial processes. In both disaster management and mining, the ability to quickly and efficiently manage water resources is essential for safeguarding human lives and minimizing environmental damage. While traditional water delivery systems have served their purpose for years, the introduction of industrial rapid flow hoses and cutting-edge technologies in industrial pipeline systems has significantly enhanced efficiency, safety, and reliability.

In emergency water supply and disaster relief, rapid flow industrial hoses are playing an increasingly crucial role by ensuring rapid and effective water delivery. Similarly, within the mining and industrial sectors, tailings pipeline systems are being transformed through automation, smart sensors, and real-time data integration. These innovations are not only making these systems more efficient but also safer and more environmentally responsible.

Part 1: Rapid Flow Hoses for Emergency Water Supply and Disaster Response

1. Understanding Rapid Flow Hoses

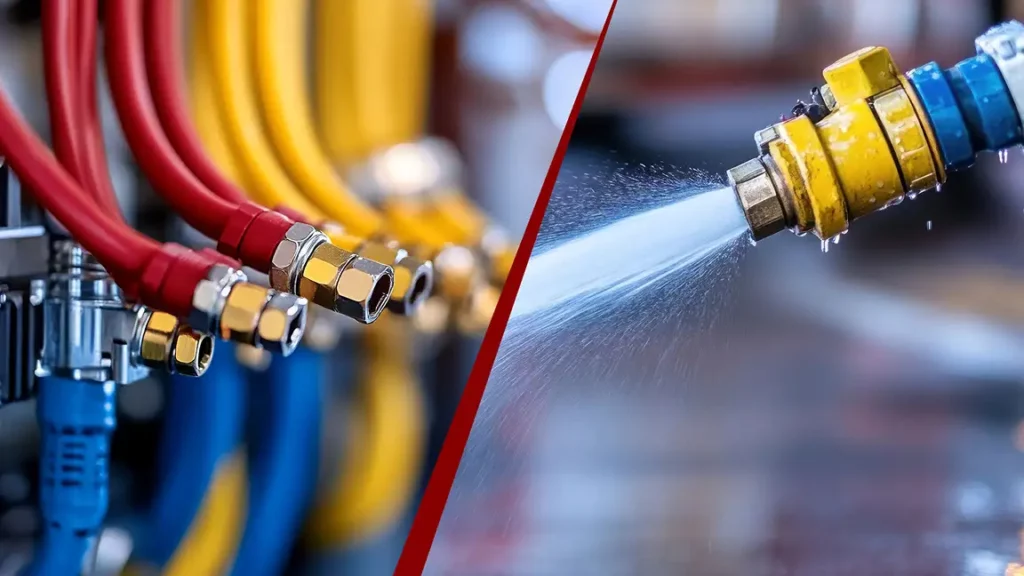

Rapid flow hoses are designed to handle large volumes of water over short periods, providing essential support during emergencies when every second counts. Unlike standard industrial hoses, which are designed for standard pressure and volume applications, an industrial rapid-flow hose can transport vast amounts of water at higher pressures, making it ideal for large-scale disaster relief, firefighting, and industrial applications.

Key Features of Rapid Flow Hoses:

- High Flow Rate: These hoses are engineered to deliver large volumes of water quickly. They can transport between 1,000 and 2,000 gallons of water per minute, ensuring fast delivery when it is most needed.

- Durability: Industrial rapid flow hoses are made from durable, high-quality materials such as PVC, synthetic rubber, and polyurethane. These materials ensure that the hoses can withstand tough conditions, such as high temperatures, rough handling, and abrasions.

- Flexibility and Portability: Despite their large size and capacity, rapid flow industrial hoses are flexible and easy to maneuver. Their portability makes them suitable for emergency response teams that need to deploy them in remote or hard-to-reach areas.

- Ease of Deployment: These hoses are designed for quick setup and deployment, reducing downtime and increasing the speed at which water can be delivered to critical areas.

Given these attributes, industrial rapid-flow hoses are indispensable tools in emergency water supply and disaster response operations. They offer an efficient and reliable means of combating fires, providing drinking water, and supporting recovery efforts.

2. Applications of Rapid Flow Hoses in Emergency Water Supply

Rapid-flow industrial hoses are crucial in emergency scenarios. They enable the quick delivery of large amounts of water in disaster response, firefighting, and areas with damaged infrastructure.

- Firefighting Operations: In remote areas or during wildfires, rapid flow hoses provide the high-pressure, high-volume water needed to fight fires, even when water infrastructure is unavailable. These hoses can be connected to nearby water sources like rivers or tanks and deployed directly to the fire, ensuring that firefighters have the resources necessary to prevent further damage.

- Disaster Relief in Floods and Droughts: In flood zones, these hoses help pump out large volumes of water quickly for rescue operations. They are essential in mitigating flood damage and ensuring rapid evacuation of residents. In drought-prone regions, industrial rapid flow hoses are used to deliver essential water to remote communities facing scarcity, helping to provide access to water for drinking, sanitation, and agriculture.

- Water Supply in Damaged Infrastructure: After disasters like earthquakes or hurricanes, rapid flow industrial hoses temporarily deliver water from external sources to affected areas until local infrastructure is repaired. These hoses serve as a crucial part of the recovery process, ensuring that essential water supply continues even when local systems are compromised.

3. The Importance of High-Flow Water Systems

Quick access to water is vital in emergency response, and high-flow water systems, like rapid flow hoses, play a crucial role in ensuring efficient water delivery. Firefighting, flood mitigation, and rescue operations all require rapid, large-scale water movement to minimize damage, save lives, and reduce environmental impact.

For example, during a wildfire, delaying water deployment can allow the fire to spread uncontrollably, threatening lives and property. Rapid flow industrial hoses ensure that first responders can quickly deliver large amounts of water to the scene, preventing further damage and enabling faster containment efforts.

In flood response, these hoses help pump out large volumes of water swiftly, reducing flooding and enabling the safe evacuation of residents. They are also useful in disaster recovery, where quick and reliable water supply systems are essential to restoring normalcy for affected communities and industries. The industrial rapid flow hose can provide the high-capacity, fast-delivery systems needed in these critical situations.

4. Advantages of Using Rapid Flow Hoses in Disaster Response

The use of rapid flow hoses in disaster management offers several key benefits:

- Speed of Deployment: Designed for quick setup, these hoses can be deployed in minutes, making them ideal for rapid-response teams. Rapid flow industrial hoses allow for fast water delivery, minimizing delays in critical situations like firefighting or flood mitigation.

- Portability and Accessibility: Thanks to their flexible design, rapid flow industrial hoses are easy to transport to challenging locations, such as mountains or flood zones, enabling effective response even in hard-to-reach areas.

- Cost-Effectiveness: These hoses offer a cost-efficient alternative by reducing the need for extensive infrastructure. Industrial rapid flow hoses provide temporary solutions, saving money for disaster relief teams while ensuring fast water supply.

- Adaptability: Rapid flow hoses can be tailored for various needs, such as pressure, temperature, or chemical resistance, making them versatile for firefighting, industrial, and disaster relief operations.

5. Integration with Other Disaster Response Systems

Rapid flow hoses are often used in tandem with other emergency response tools to create a more effective and efficient response system. For example:

- Water Pumps and Reservoirs: Hoses can be connected to high-capacity water pumps and reservoirs, enabling responders to pump water over long distances.

- Automatic Shutoff Valves: In some applications, hoses are integrated with automatic shutoff systems that stop water flow if there is a blockage or system failure, ensuring the safety of both personnel and the environment.

- Drones and Remote Sensors: In some advanced applications, rapid-flow industrial hoses may be combined with drones or other remote sensing devices to monitor water delivery or even guide responders to critical areas that need water.

This level of integration allows for more efficient and coordinated emergency operations.

Part 2: Revolutionizing Tailings Pipeline Systems with Automation, Smart Sensors, and Real-Time Data Integration

1. The Challenges of Traditional Tailings Pipeline Systems

In mining and industrial applications, tailings—the waste byproduct generated during ore extraction—present significant challenges. These tailings are typically transported via pipelines, and managing these systems effectively is crucial for operational efficiency and environmental responsibility. However, traditional tailings pipeline systems encounter several obstacles, including:

- Leaks and Environmental Contamination: The risk of tailings leaking into the surrounding environment is a major concern for mining operations. Even small leaks or spills can lead to environmental disasters, causing long-term damage to ecosystems and human health. Rapid flow hoses provide a safer alternative by offering more reliable water and tailings transport, reducing the likelihood of leaks and spills.

- Frequent Maintenance and Downtime: Traditional tailings pipelines often require frequent maintenance due to issues such as corrosion, blockages, and wear. This results in costly downtime and disrupts operations. Industrial rapid flow hoses offer a more durable and low-maintenance solution, reducing the need for continuous repairs and minimizing operational disruptions.

- Safety Hazards: Workers managing tailings pipelines face risks like exposure to hazardous chemicals and pipeline failures. These dangers can lead to serious injuries. The use of rapid flow industrial hoses can reduce manual intervention, minimizing exposure during water or tailings transport, and improving worker safety by ensuring smoother and more secure operations.

These challenges underscore the need for advanced technologies, such as rapid flow hoses, to improve the efficiency, safety, and environmental sustainability of tailings management. Industrial rapid flow hoses provide a more reliable solution, addressing the issues faced by traditional pipelines, reducing risks, and enhancing overall performance.

2. The Role of Automation in Tailings Pipeline Systems

Automation is becoming increasingly important in optimizing tailings pipeline systems. By incorporating automated controls, remote monitoring, and robotic maintenance systems, mining operations can significantly reduce operational costs, downtime, and safety risks.

- Automated Monitoring Systems: Automation allows for continuous, real-time monitoring of pipeline conditions, including pressure, temperature, and flow rate. This data is transmitted to centralized control systems, allowing operators to detect potential issues before they become critical problems. Similarly, rapid flow industrial hoses benefit from such systems, ensuring efficient and reliable water delivery during emergency operations by allowing for quick adjustments when needed.

- Remote Control and Adjustment: Automated systems can adjust water flow and pressure or even activate emergency shutoff valves without human intervention. This increases system efficiency while minimizing the need for manual labor in potentially hazardous environments. With industrial rapid flow hoses, automation enhances the ability to control flow rates and ensures optimal operation during both routine and emergency situations.

- Improved Predictive Maintenance: Automation also aids in predictive maintenance by utilizing data analytics to forecast equipment failures and identify potential weak points in the pipeline, preventing expensive downtime. This predictive approach ensures that rapid flow hoses are always functioning optimally, reducing the chances of unexpected failures.

In addition to these benefits, rapid flow industrial hoses play a key role in ensuring the smooth and efficient transport of tailings and water. They complement the automation technology that streamlines the entire pipeline system, contributing to better overall performance and reliability.

3. Smart Sensors: The Future of Tailings Pipeline Monitoring

Smart sensors are transforming tailings pipeline monitoring by providing real-time data for proactive system management.

- Flow Rate Sensors: These detect changes in flow, alerting operators to potential blockages or leaks.

- Pressure Sensors: Monitoring pipeline pressure helps identify issues like corrosion or blockages, enabling quick responses.

- Temperature and Chemical Sensors: These sensors track temperature and chemical changes, detecting potential hazards.

Operators can enhance efficiency, safety, and system management by integrating smart sensors with industrial rapid-flow hoses.

4. Real-Time Data Integration for Improved Decision-Making

Real-time data integration is transforming tailings pipeline systems by providing operators with up-to-date insights for better decision-making.

- Real-Time Dashboards: Sensor data is displayed on centralized dashboards, giving operators a comprehensive view of system performance. This allows for early issue detection and proactive management.

- Predictive Analytics: Real-time data is analyzed using machine learning and AI algorithms to predict future system behavior, optimize maintenance schedules, and prevent pipeline failures.

- Automated Alerts and Responses: Automated systems send alerts for anomalies, and in some cases, take corrective actions such as shutting down sections of the pipeline to prevent further damage.

For industrial rapid flow hoses, real-time data integration is essential in ensuring the safe and efficient operation of high-capacity water delivery systems, enhancing decision-making during emergency responses and optimizing hose use in industrial and disaster relief scenarios.

5. Enhancing Safety and Environmental Impact with Technology

Modernizing tailings pipeline systems with automation and smart sensors greatly improves safety and environmental impact.

- Leak Detection: Smart sensors detect leaks early, preventing contamination and limiting damage. Automated systems can shut off water flow to the affected area, ensuring industrial rapid-flow hoses safely contain water or tailings and avoid spills.

- Environmentally Friendly Tailings Disposal: Advances in pipeline technology optimize operations and reduce leaks. Integrating rapid flow industrial hoses ensures efficient water flow management, enabling safer and more sustainable tailings disposal.

- Safer Working Conditions: Automation reduces the need for workers to handle hazardous pipeline sections. Industrial rapid flow hoses help minimize manual intervention, enhancing safety by protecting workers from exposure to dangerous chemicals and environments.

6. Future Trends in Tailings Pipeline Systems

As technology evolves, several exciting developments are shaping the future of tailings pipeline systems:

- AI and Machine Learning: These technologies will improve predictive maintenance, anomaly detection, and system optimization, ensuring the optimal use of rapid flow industrial hoses and minimizing system failure risks.

- Sustainable Mining Practices: With growing sustainability pressure, tailings systems will adopt eco-friendly materials. Rapid flow hoses will evolve to use environmentally responsible materials, promoting sustainable water and tailings management.

- Advanced Data Analytics: Data analytics will optimize tailings transport and processing, enhancing the efficiency of industrial rapid flow hoses and reducing operational costs.

Conclusion

Technology is revolutionizing industries, from rapid flow industrial hose solutions enhancing emergency water supply to automation and data analytics optimizing tailings pipeline management. These advancements boost efficiency, safety, and sustainability.

Rapid flow industrial hose solutions enable quick responses in emergencies, while automation and data integration improve tailings management in mining, reducing environmental risks and enhancing performance.

As technology evolves, we can expect even greater improvements in efficiency and sustainability, ensuring a more resilient future.