Dredging Hose Built Tough

Our dredging hose is built to withstand highly abrasive applications while retaining flexibility.

Contact A Dredging Expert!

Call: (760) 821-8112

Email: info@daepumps.com

30+ Years In Dredging Experience

Over multiple decades in the dredging industry, we are experienced in a wide array of projects and applications.

High-Quality Slurry Hose

Built with thick inner rubber liners designed to maximize flow and throughput while retaining long lasting durability.

We Price Match or Beat on all sizes of slurry discharge hoses,

Contact Us to get the best deal!

We Ship With Free Hardware

We ship all our hoses with the hardware needed to install FREE! Save yourself the trip to the local hardware store.

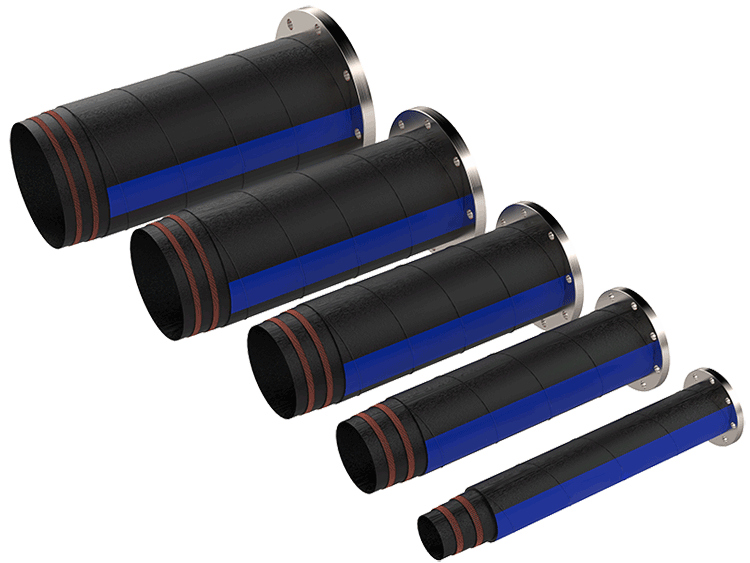

Multiple Sizes Available

We offer our high-quality slurry hose in 4″, 6″, 8″, 10″ and 12″ sizes to fit all types of applications.

Built With Abrasion In Mind

- Capable of Handling High Solids

- High Viscosity/Gravity Pumping

- High Abrasives Pumping

- Low pH & Chemical Pumping

- Designed to Prevent and Reduce Clogs

- Results in Longer Lifespan & Minimal Downtime

Price Match Or beat

We Strive To Provide The Best Deal For Dredge Hoses For Our Customers,

Contact Us To Get The Best Price